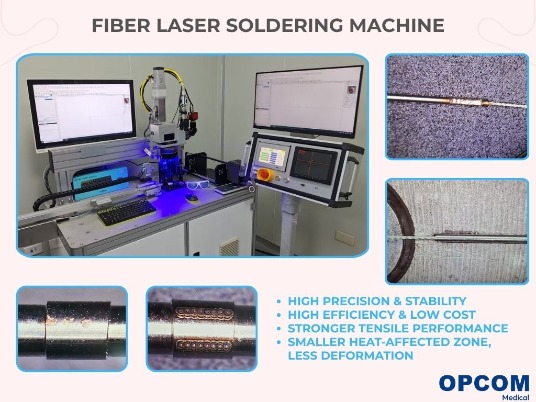

At OPCOM Medical, innovation drives everything we do. By adopting Fiber Laser Soldering Technology, we’re enhancing the manufacturing process for bending section adapter ring soldering as well as wire rope cutting and soldering. This advanced approach raises the bar for precision and efficiency in medical device manufacturing.

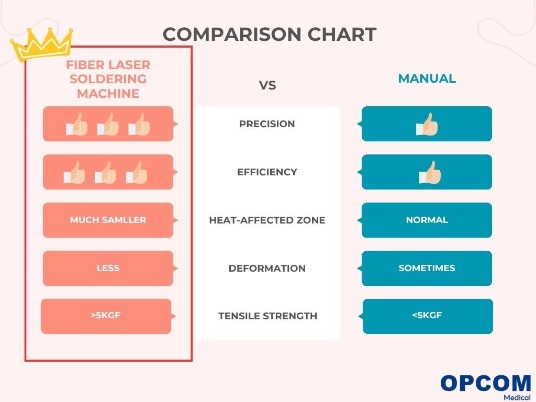

Compared to manual soldering, fiber laser soldering ensures better performance and reliability—helping us bring safer, higher-quality products to patients worldwide.

- Why Fiber Laser Soldering?

- High Precision & Stability – Every bond is accurate and repeatable

- Minimal Heat Impact – Less deformation, stronger durability

- Fixed Solder Joint Spacing – Ensuring uniform and consistent assembly

- Tensile strength Above 5 kgf – Reliable bonding strength for demanding applications

- Consistent Reliability – Uniform results at scale

- What this means for our partners:

- Faster project timelines → quicker prototype validation and market launch

- Reliable quality at scale → confidence in every production run

- Innovation edge → access to advanced manufacturing that sets your brand apart

We’re excited to continue pushing the boundaries of what’s possible in medical device manufacturing.